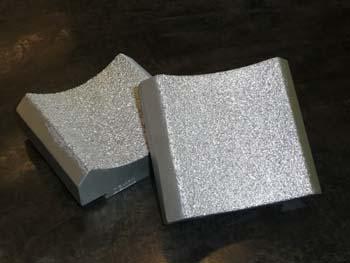

True-Grit Wrap-Around Dies

Eckel Non-Marking True Grit® Dies - Have set a NEW industry standard for handling Corrosion Resistant Alloys (CRA) tubular goods. Eckel True Grit® Dies are used on chrome tubulars where reduced die penetration and die marking is greatly desired. Eckel's Coated True Grit® Dies utilize Tungsten Carbide grit which provides many more points of contact on the surface of the tubular than our Pyramid Fine Tooth dies. The Tungsten Carbide is a dense, metal like substance that does not flake or sheer off the face of the die. A head conversion kit for conversion of your head assembly to a head assembly for running chrome is required to obtain optimal performance from the True Grit® Dies. It is highly recommended to change the bushings in the roller after every job.

True Grit® Dies

Eckel's True Grit® Dies last up to 3 times longer than other manufacturers grit faced dies- Resilience / Long-Lasting - up to 3X Longer - Field tests have shown that Eckel's True Grit® Dies last up to 3 times longer than other manufacturers grit faced dies.

- Heat Treating - Eckel's Coated True Grit® Dies are heat treated and do not deform. This allows the die to be easily removed from the head after a job and stored for future use.

- Performance - Eckel Coated True Grit® dies perform better than any steel tooth die when running (SUPER or HYPER) Chrome as these type tubulars are as hard or harder than heat treated steel dies.

- Penetration - True Grit® Die penetrations are typically less than half of API allowable surface defect depth.

- Contamination - True Grit® minimize die clogging dirt, paint and varnish from tubulars.

- Custom Sizes - Eckel Coated True Grit® dies are available for any model of Eckel tong.

Based in United States

Local time:

Date:

Sales Question or Technical Support?

Eckel Sales Representative

8035 North County Road WestOdessa, TX 79707

Ph: +1(432) 362-4336

Fax: +1(432) 362 1827

sales@eckel.com